|

For variable speed applications that require maximum effeciency, grid connected or not, the permanent magnet synchronous or BLDC motor connected through a drive that pulse width modulates the voltage to the motor has dominated. Now there is an alternative. The wound field synchronous motor with a resonant field exciter provides an independently adjustable rotor flux over a range of 4:1 or more, eliminating the need to PWM the voltage to the motor.

World's Simplest Motor Drive

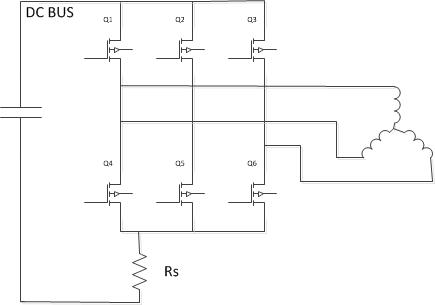

While this is a conventional three phase bridge, when driving a wound field synchronous motor with resonant field exciter, each semiconductor is turned on and off in a trapazoidal sequence at the frequency of rotation of the motor poles, which is typically under 400 Hz, rather than the 4KHZ to 20KHZ rate of a conventional motor drive. This simplifies many tough design issues such as managing switching losses and EMI. This structure is actually a smaller version of large wound field synchronous motor drives that have been used for years.

The new twist is that the single current sense resistor monitors motor current and provides feedback to the Resonant Field Exciter to maintain motor speed as well as provide overcurrent protection.

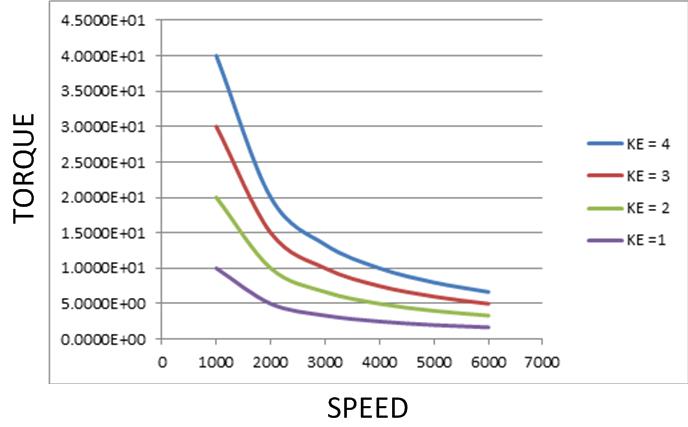

Electronic Gearing

High torque/ low speed and high speed/ low torque in the same motor with the worlds siimplest drive is achievable, just by changing the rotor field through the resonant field exciter.

In many applications the wound field synchronous motor with resonant field exciter can reach all the required system operating points, without resorting to PWM of the motor voltage.

|