|

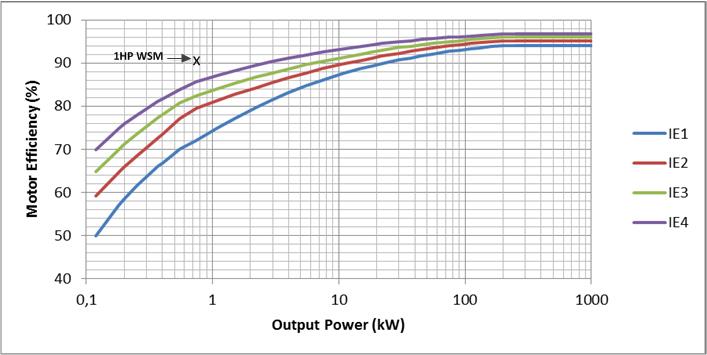

The wound field synchronous motor has been the motor of choice above 400 HP for over 100 years, but it's been conspicously absent in discussions of how to achieve IE4 motor effeciency performance.The Resonant Field Exciter changes all that, enabling direct line connected IE4 operation with no inverter. All with a motor mounted device as small as 2 cubic inches per HP running at 1/30 to 1/40 the shaft power of the motor.

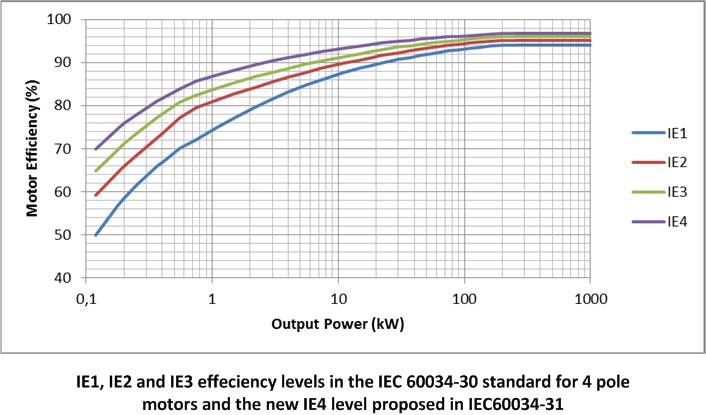

The International Electrotechnical Commission (IEC), an international, non-government, consensus based standards organization founded in 1906, has established four levels of motor efficiency to date.

In the U.S. Congress raised the bar on electric motor efficiency, to the IE3 level, effective in 2010. The world will be quick to follow. By 2017 the IE3 minimum efficiency standard will be the law of the land for new grid connected motors manufactured almost worldwide.

At the moment, there is no legislation in process anywhere in the world to implement IE4. At least not yet. But there it sits as the "holy grail" of motor efficiency. Many OEM's that use IE2 motors in their products aren't waiting for legislation. In the pump, compressor or HVAC worlds IE4 provides a significant competitive advantage over the IE2 motors they now have to design out. As long as they have to pull out a white sheet of paper, they might as well go IE4 if they can.

But IE4 technology can be expensive. Induction motor technology alone can't get there without adding electronic drives, and not every induction motor can be driven by an electronic drive. Permanent magnet technologies also need drives and have the hidden variable cost and long supply chain of rare earth magnets. Switch reluctance technology is so different from conventional motor and drive manufacturing that a new manufacturing infrastructure must be built to provide them in volume, and they can be noisy.

However, by designing in Digital Power Engineering's Resonant Field Exciter technology to provide field power to a wound field synchronous motor equiped with a amortisseur rotor winding for starting, the system will achieve IE4 performance with no magnets and no inverters or electronics between the grid and the motor stator. Where a WSM-RFE would fit on the chart is illustrated below.

|