|

As electric motion has become more complicated over the last 30 years, the Law of Unintended Consequences has taken its toll. Undesirable side effects such as electromagnetic interference (EMI), bearing degeneration and motor insulation breakdown have reared their ugly heads. Complex filtering, grounding and shielding, as well as significant develpment expense is needed to mitigate these effects.

The wound field synchronous motor with the resonant field exciter and a simple current limited commutator or direct grid connection eliminates all that by simply avoiding the problem.

Electromagnetic Interference (EMI)

Induction motors, permanant magnet synchronous motors and swirched reluctance motors all require controlling the full power to the motor. To do this, the voltage to the motor is pulse width modulated at frequencies up to 20Khz.

Alone among all motor technologies, the wound field synchronous motor allows idependent control of rotor and stator fields, and only one need be used for torque and speed control. Since the rotor power is only 3 to 4% of the output power, using the rotor power for control results in a dramatic reduction of the EMI footprint of the system.

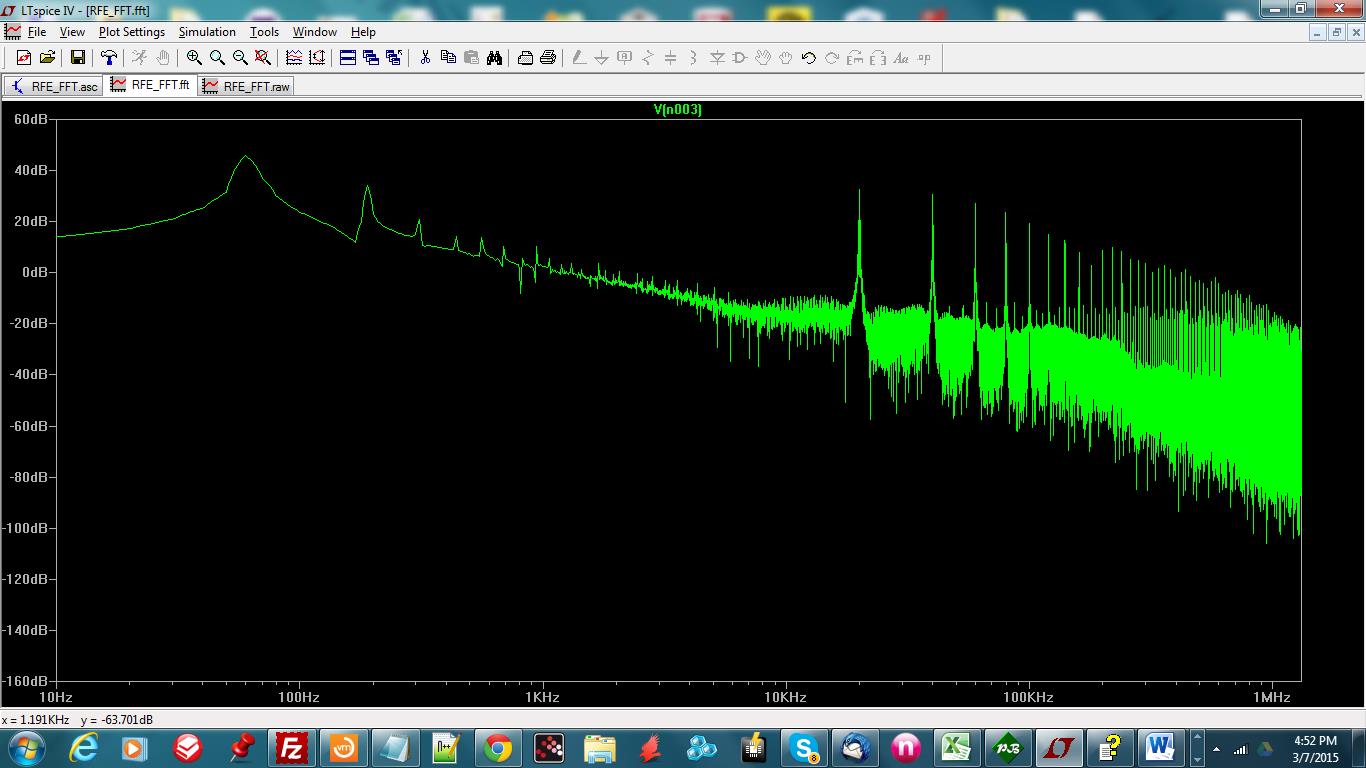

Motor Voltage Spectrum; Conventional VFD

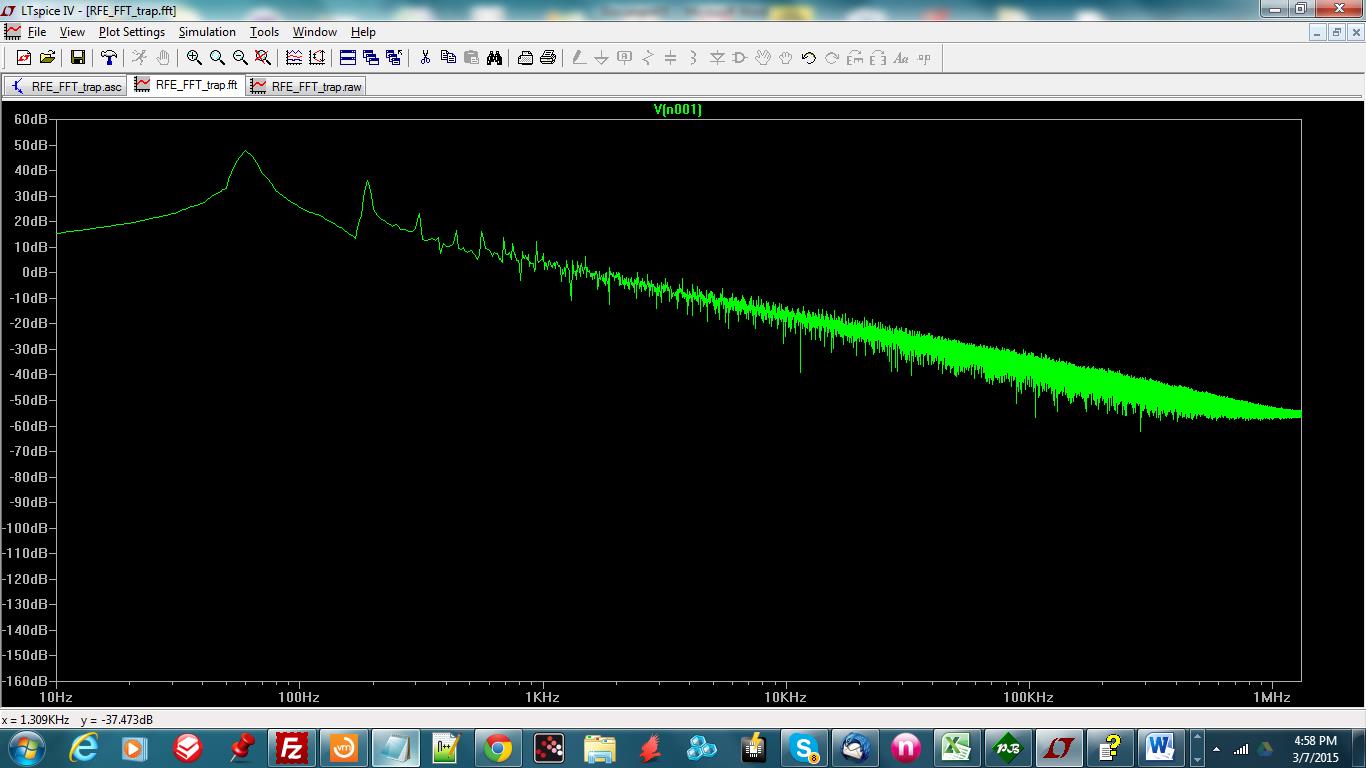

Motor Voltage Spectrum; WSM with RFE

Bearing Degeneration

All conventional high effeciency motor technologies require electronic inverters between the power source and the motor stator and all of these inverters generate high frequency square wave voltages to drive the motor with. Meanwhile, motor bearings impose a thin layer of lubricant between the motor shaft and the electrically grounded stationary part of the bearing. If the voltage on the motor windings are not perfectly balanced (and they rarely are) any imbalance can show up as a voltage on the motor rotor. Eventually this voltage discharges through a spark through the lubricant film, pitting the bearing and degrading it a little with each discharge causing an effect called bearing fluting. This gets worse with higher PWM frequencies.

Example of Bearing Fluting

Since the wound field synchronous motor has a rotor that is independently powered by the resonant field exciter, there need not be any high frequency PWM on the motor stator and there would be little or no high frequency voltage imbalance to cause a discharge through the bearings and lead to bearing degeneration.

Motor Insulation Breakdown

Induction motors in particular are designed to see only 50 or 60 Hz sine wave power. If not specificly designed for the high frequencies and sharp voltage transitions of conventional PWM motor drives, the motors can be subjected to electrical stresses they were not designed for leading to premature insulation failure.

The wound field synchronous motor with the resonant field exciter does not require that the stator voltage be PWM driven. If the motor is direct grid powered, stresses are no more than in a conventional motor. If the motor has a current limited electronic commutator, running at 5 to 100Hz, the stresses are only slightly higher than the line operated case and there would be no danger of insulation breakdown.

|